NEXT-LEVEL CARBON COMPOSITES

Our groundbreaking technology has the potential to revolutionize a range of industries and make a positive impact on the world as we know it.

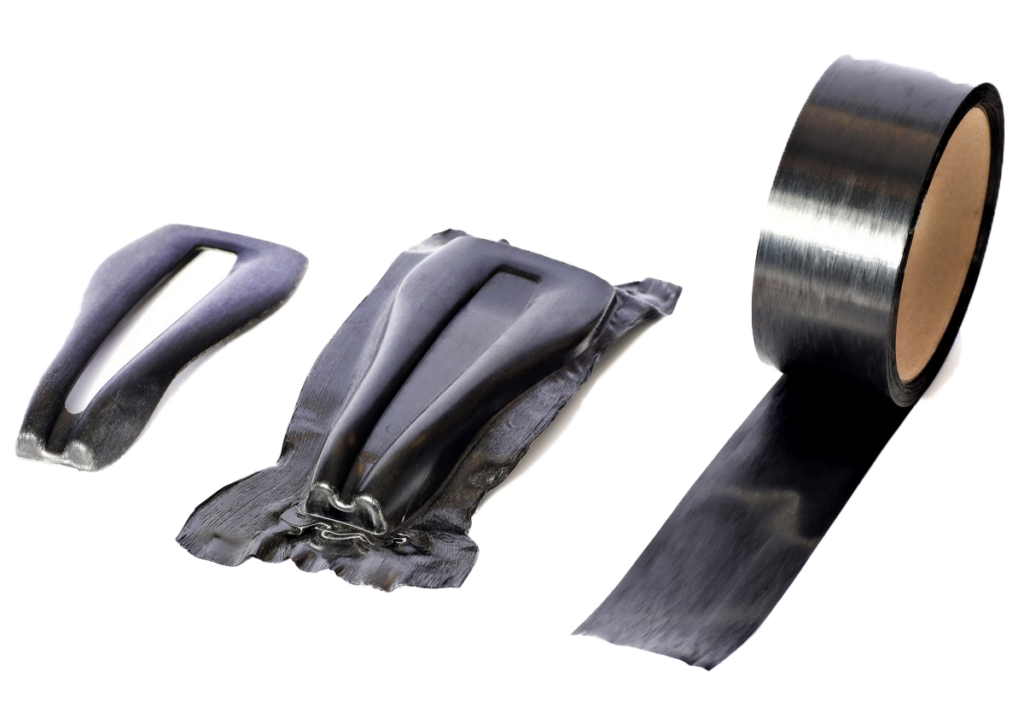

ANTIUM is the outcome of Re:Build Maufacturing’s breakthrough technology that combines high-pressure forming with advanced carbon fiber and polymer materials. It’s disrupting an array of industries, turning items previously made with aluminum, titanium, plastic, or traditional composite materials into the next-generation products consumers want.

Dream Bigger.

Dream Better.

ANTIUM combines continuous fiber-reinforced thermoplastic materials with a unique, high-pressure stamp-forming process to create highly structural, damage-tolerant composite components. In fact, when compared to traditional thermoset composites, ANTIUM is nearly 5 times as durable and is substantially more resistant to permanent structural damage.

TOUGH

ANTIUM’s highly durable and robust structure will ensure products can withstand even the most complex tasks. Utilize the strong qualities of ANTIUM to push products to the next level.

LIGHT

Strength without the weight! ANTIUM materials are significantly lighter than traditional materials such as aluminum and steel, without sacrificing material strength.

RESPONSIVE

With its unique layered design, ANTIUM can both flex and support products based on need. When it comes to design, the sky’s the limit!

Competitive Advantages in Various Industries

How It’s Made

ANTIUM is revolutionary because of how it’s made. By combining fiber-reinforced composites with advanced thermoplastics with a high-pressure forging process, our process engineers and materials science teams have elevated composite materials to a new level.

Take your product to the next level!

We believe that innovation is the key to solving the world’s problems. We are dedicated to pushing the boundaries of material science and developing thermoplastic composites that will change the world!